Steel sheet piles can offer an environmentally friendly solution that is sustainable in terms of environmental social and economic impact.

Steel is a permanent material: never consumed, but continuously transformed; the use of natural resources for producing steel the first time is therefore a transformative process, making iron available in a more “practical form” for subsequent uses (life cycles) and thereby reducing the medium/long term pressure on natural resources.

Steel Sheet Piles can be made from recycled steel, can be re-used and recycled. Sheet Piles are low displacement piles so leave the ground almost intact following their removal from a site.

Best Practice

In order to ensure that a solution provides the best performance in sustainability the following standards should be consulted (where applicable links are given to BSI as publisher of the British Standard version of international standards).

For quality, the production process should be in accordance with BS EN ISO 9001:2015 Quality Management.

To ensure the health and safety of those involved in production the production process should be in accordance with BS OHSAS 18001:2007 – Occupational Health and Safety Management.

For environmental performance the production should be in accordance with BS EN ISO 14001:2015 Environmental Management Systems and BS EN ISO 50001 Energy Management Systems

Furthermore, certification to BES 6001 Responsible Sourcing of Construction Products demonstrates by third party assessment that the sheet piles are produced sustainably using responsible sourcing. Details can be viewed at www.greenbooklive.com.

In addition to conformity to the abovementioned standard, best practice would be to use a supplier that reports clear indicators of environmental performance such as an Environmental Product Declaration. This should be an independently verified document that communicates transparent and comparable information about the life-cycle environmental impacts of the products. For comparison of alternative solutions, one should consider Life Cycle Assessment (LCA) methodology, performed through the different steps of production, installation use and end of life scenarios.

An example EPD from a member of the SPG is available at https://sheetpiling.arcelormittal.com/download-center/epd-lca-download/

An example embodied carbon calculator has been provided to SMEs by SPG member organisation Tony Gee and Partners and can be downloaded from their website

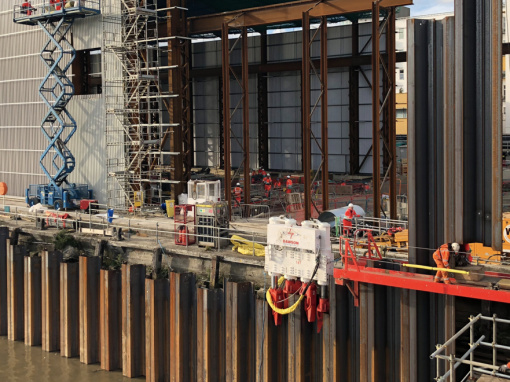

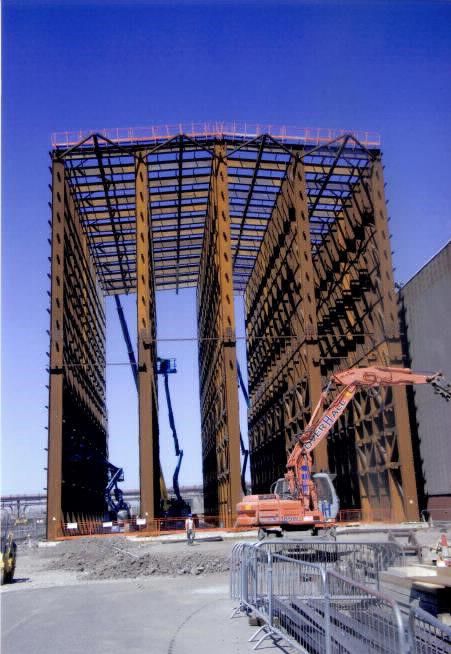

Case Studies

A selection of our work

Steel Piling Group, C/O SCI, Silwood Park, Unit D, Buckhurst Road, Ascot ,Berkshire. SL5 7QN

E: info@steelpilinggroup.org

© Copyright 2018 Steel Piling Group

Terms & Conditions | Privacy Policy